IF heat treatment furnace

Features:

Application: Hardening , Quenching & Tempering

Material Heated:45#,40Cr,42CrMo,65Mn

Bar Diameter Allow: Φ20-110mm

Pipe Diameter Allow: Φ60-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Product Name: IF heat treatment furnace

Typical Application:

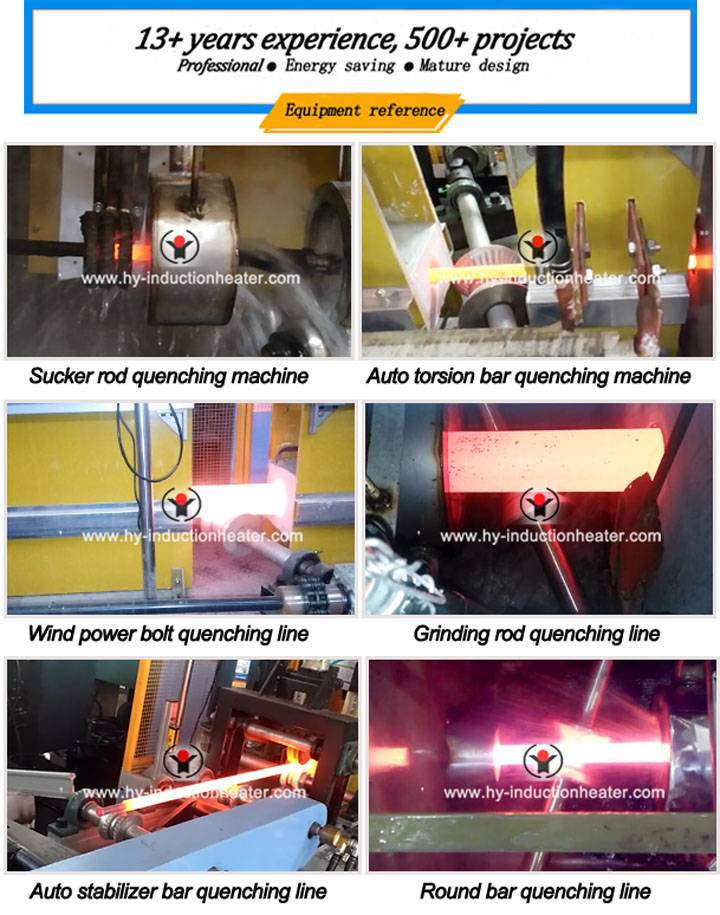

IF induction heat treatment furnace is widely applied in hardening, quenching and annealing field. The power of IF heat treatment furnace can be 100-8000KW, which is using induction heating process,automatic feeder,new type power supply and quality raw material.

Advantages for IF heat treatment furnace

- High reliability:Adopt famous brand components of IGBT converter which reduce fault rate and make sure the equipment can run reliably.

- Safe and reliable.There are reliable protection covers for the mechanical rotating parts,which is durable and very safe for operators. Automatic protections for water temperature,water pressure,phase shortage,overcurrent and undervoltage.

- Easy installation & commission and simple operation.

- Transmission mechanism frame has sufficient strength and rigidity for ease of installation of equipment

- Feeding and discharging table is using high quality steel welded firmly, which can withstand a certain impact load.

The characteristics of IF heat treatment furnace are as follows:

- (Fine grain and high hardness on the surface. After induction quenching,fine martensite structure will be obtained. The hardness of the martensite is 2 – 3HRC higher than that of the conventional quenching, and the core basically maintains the microstructure and properties before heat treatment.

- The heating speed is very fast and the heating time is very short. It usually takes only a few seconds to dozens of seconds to complete. Workpiece is not easy to produce oxidative decarburization, quenching deformation is also very small.

- High thermal efficiency, high productivity, good production environment, easy to realize mechanization and automation.

- The depth of hardened layer is easy to control. The depth of the hardened layer is controlled by controlling the current frequency.

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-v110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

| Pipe diameter | Automatic control | Power design |

| Ø95,Ø114 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø73.2,Ø88.9,139.7 mm(Drill pipe) | IPC Control | KGPS500KW Quenching+KGPS100KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

As our induction heater is all customized, the above parameters are only for your reference.

Welcome to contact us at tom@foreverfurnace.com for more detailed price & solution.

Contact person: Hailee Ma

Email:sales@foreverfurnace.com

Phone: 0086-18932783253(whatsapp, wechat)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.